Chain maintenance

The applicable accident prevention regulations and the specifications of DIN EN 818-7 and DIN 685 Part 5 must be observed for all maintenance work. The assembly, disassembly, reassembly, commissioning, operating and maintenance conditions specified by the manufacturer of the lifting device must also be observed.

Regular lubrication of the round steel chain can achieve a 15-20 times higher number of load cycles than with a dry, unlubricated chain. We recommend lubricating the entire length of the chains before commissioning. Ensure that all chain links are lubricated. No chain link should be overlooked, as this could lead to premature wear.

When lubricating the hoist chains, ensure that the lubricant penetrates into the chain joints subject to wear. Changeover links must be lubricated with particular care. Changeover links are the chain links that come to a standstill at a constant lifting distance when switching from the lifting to the lowering movement on or directly at the inlet of the drive and return sprockets. These chain links are subjected to particularly high loads due to dynamic vibrations and must therefore be carefully lubricated at short intervals. The selection of a suitable lubricant depends on the place of use and the prevailing ambient conditions. A corresponding lubricant recommendation can be requested from RUD.

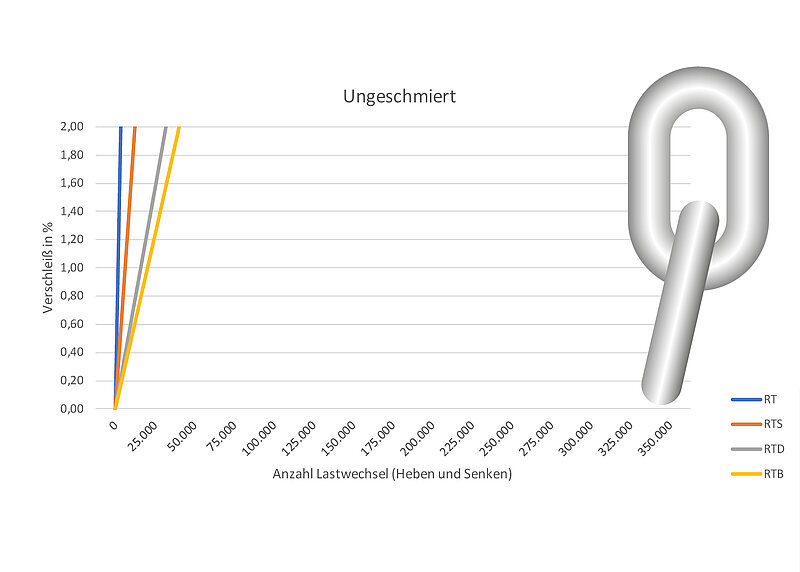

Without chain lubrication

Load cycle figures with unlubricated chain:

- When running over drive and return sprockets, the chain links are bent under load.

- To minimise joint friction, hoist chains should be lubricated at regular intervals depending on the operating conditions.

The specified load cycles were achieved with an unlubricated chain at a load tension of 1OO N/mm2, pocket wheel Z = 5 and speed V = 8 m/min.

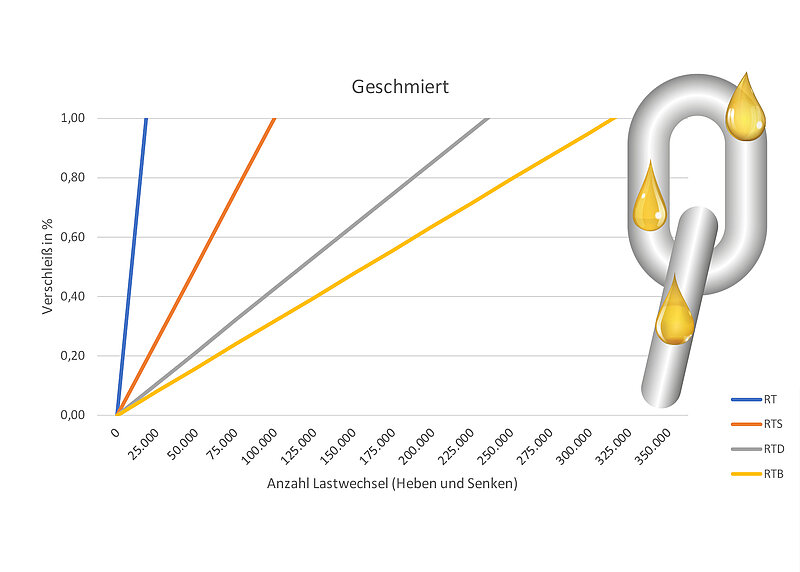

Regular chain lubrication

Number of load cycles with lubricated chain:

- Regular lubrication can achieve a 15 to 20 times higher number of load cycles than with a dry, unlubricated chain.

- When lubricating, ensure that the lubricant penetrates into the joints subject to wear.

The specified load cycles were achieved with a continuously lubricated chain at a load capacity of 1OO N/mm2, pocket wheel Z = 5 and speed V = 8 m/min.